UK - London Branch

CANCELLED Edward Snell

LONDON Dana Centre Wellcome Wolfson Building, 165 Queen's Gate, Kensington, LondonLIFE & TIMES OF A YOUNG WEST COUNTRY ENGINEER [...]

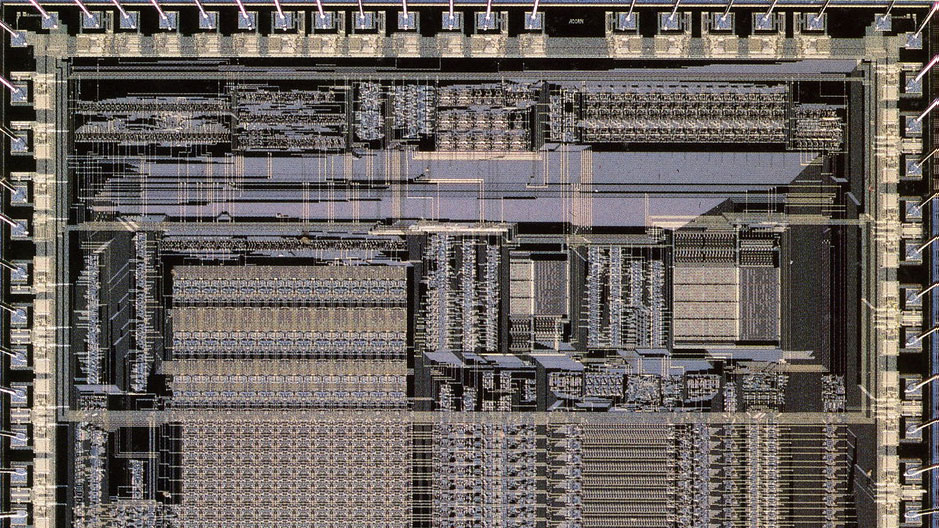

POSTPONED tbc History of ARM and Trends in AI

LONDON Dana Centre Wellcome Wolfson Building, 165 Queen's Gate, Kensington, LondonTHE DICKINSON MEMORIAL LECTURE: A presentation by Professor Steve [...]

“A curator at the height of his powers: HW Dickinson, James Watt, and the Newcomen Society, 1919-1930” by Ben Russell

LONDON Alan Baxter Gallery 75 Cowcross St, Clerkenwell, London“Metallurgical Myths and Other Misapprehensions of the Jet Engine and Jet Aircraft Era” by Dr.Fred Starr

This is an Online EventRepeated statements that the development of the jet engine was held up by the shortcomings of high temperature alloys for turbine blades are without foundation. Frank Whittle, given the funding, could have had a jet engine prototype running by 1932-33. And the RAF could have been equipped with jet fighters by 1939. It was unfortunate that Griffith (of Griffith Crack Fame) was so opposed to the jet engine principle, probably because he saw this as a rival to his own weird turboprop ideas. Accordingly, funding was withheld, the Germans taking the lead. Coming to more recent times, the shortcomings of materials helped wreck the prospects for Concorde and the proposed American Supersonic Transport. It is a feature of supersonic flight that better range and payload are obtained by flying as fast as possible. Concorde was designed for Mach 2.2, but couldn't fly continuously at that speed. The American SST was intended for Mach 2.7. Flying fast does mean, however, aerodynamic heating, requiring “heat resistant” airframe alloys. Concorde, in my view, needs to be seen as an engineering failure, because, in part, of the fall off in strength of aluminium alloys above 120 deg C, meant it was unable to cruise at the proposed design speed. Similar issues beset the American SST, although it was using titanium. Recent projected “business jet” supersonic transports dodge the materials issue by flying at around Mach 1.7. They are aerodynamically inefficient, but better engine performance and the ability of millionaire passengers to pay top value fares, might make such aircraft a viable proposition.

“Industry before the industrial revolution” by Dr Justine Bayley

LONDON Alan Baxter Gallery 75 Cowcross St, Clerkenwell, LondonThe 18th century is often seen as the beginning of industrialisation in Britain, but there had already been significant changes in the methods and scale of production in many industries in the preceding centuries. While some 18th-century developments were indeed revolutionary, others built on previous innovations – which themselves had both technical and economic drivers. In the latter part of the first millennium most craftsmen worked in small groups or on their own, and the things they made were mostly ‘one-offs’. There were some changes to the scale of production over the following centuries but major technical changes only become important at the very end of the medieval period. This talk will explore and illustrate some of changes that took place across a range of industries – mainly metals, glass and ceramics – and will discuss the benefits they brought. This is a hybrid meeting which can be attended in person or by using Zoom.

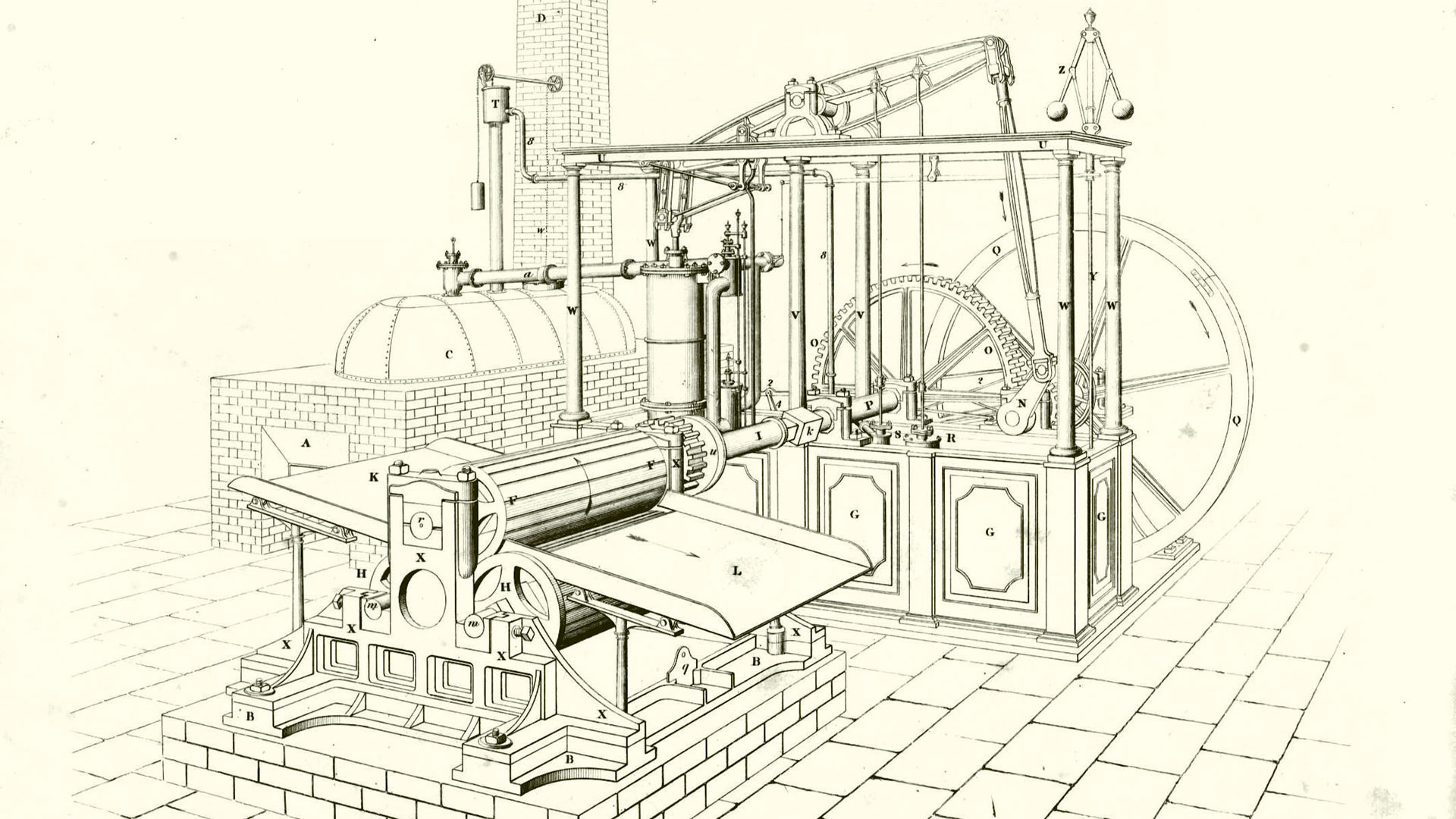

Industrial Steam Power In London 1780 – 1805

LONDON Alan Baxter Gallery 75 Cowcross St, Clerkenwell, LondonAn in-person and streamed (Zoom) lecture by Dr. John [...]

The Call To Arms (Dickinson Memorial Lecture) by Stephen Furber

LONDON Alan Baxter Gallery 75 Cowcross St, Clerkenwell, LondonAn in person and online presentation by Professor Stephen [...]

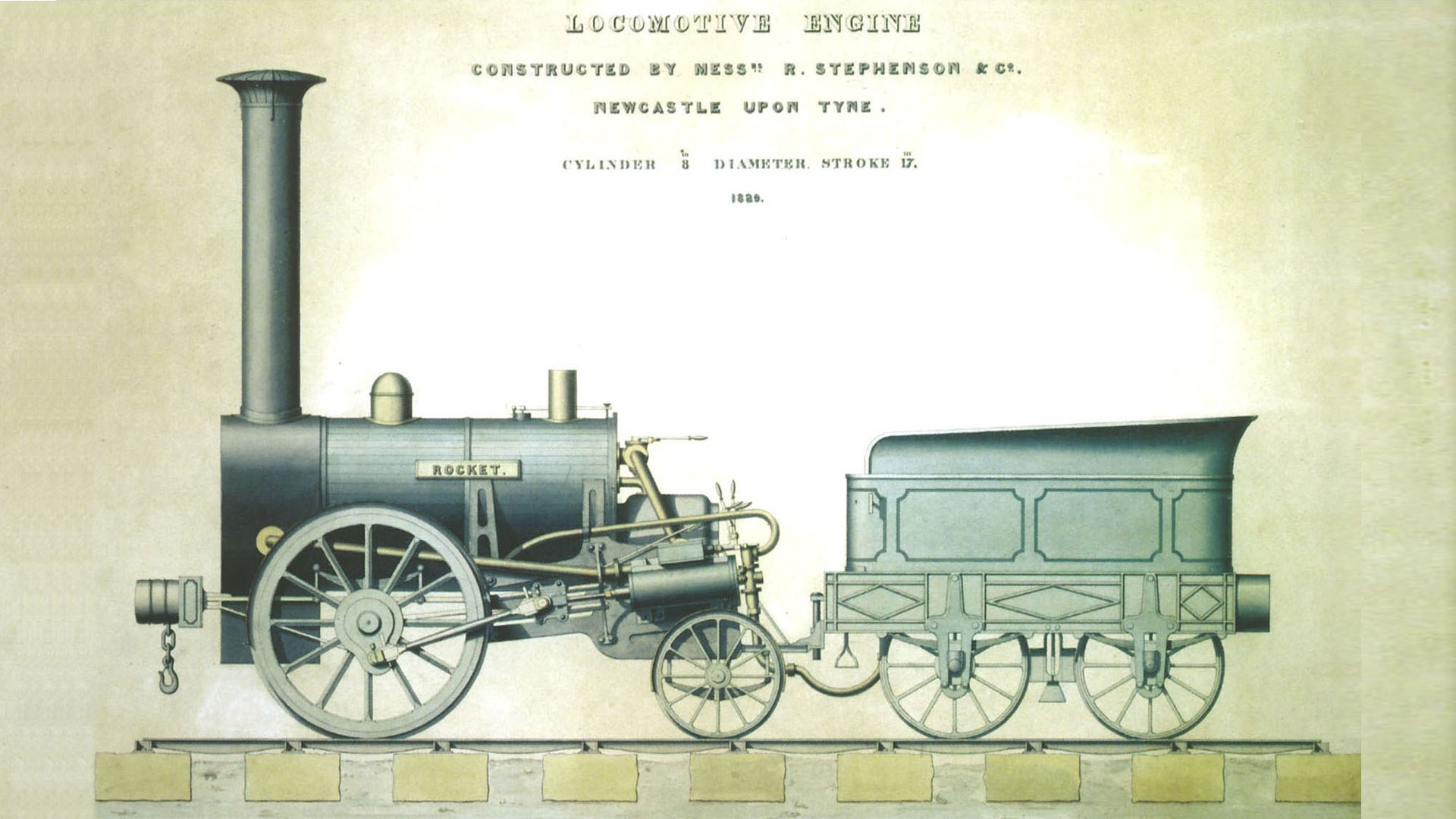

‘Learning Through Archaeology: The ROCKET Project’ by Michael Bailey

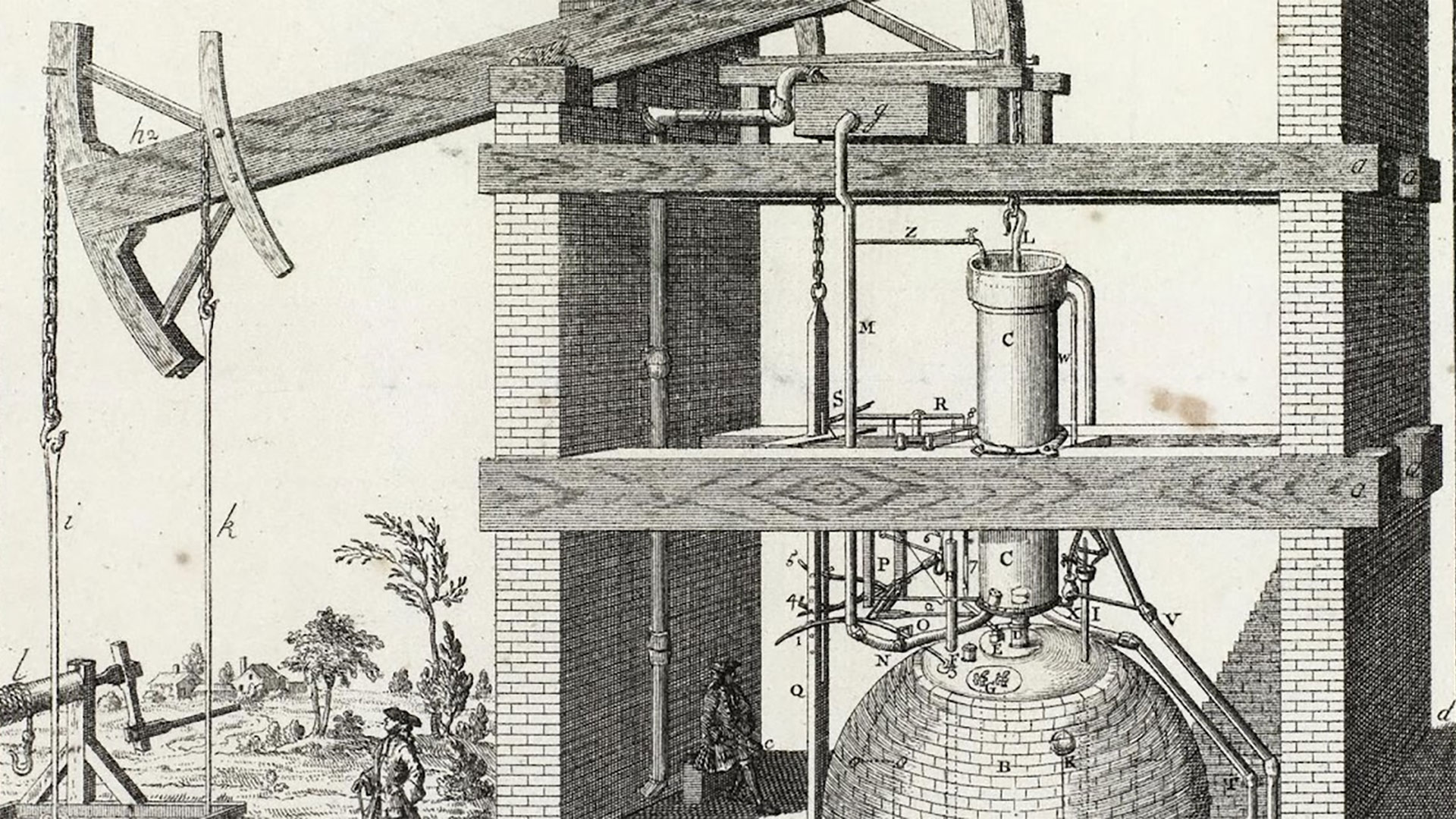

LONDON Alan Baxter Gallery 75 Cowcross St, Clerkenwell, LondonTHIS EVENT IS POSTPONED : ‘Newcomen Engine illustrations’ by David Perrett

LONDON Dana Centre Wellcome Wolfson Building, 165 Queen's Gate, Kensington, LondonThis event is postponed due to rail strikes. Please [...]

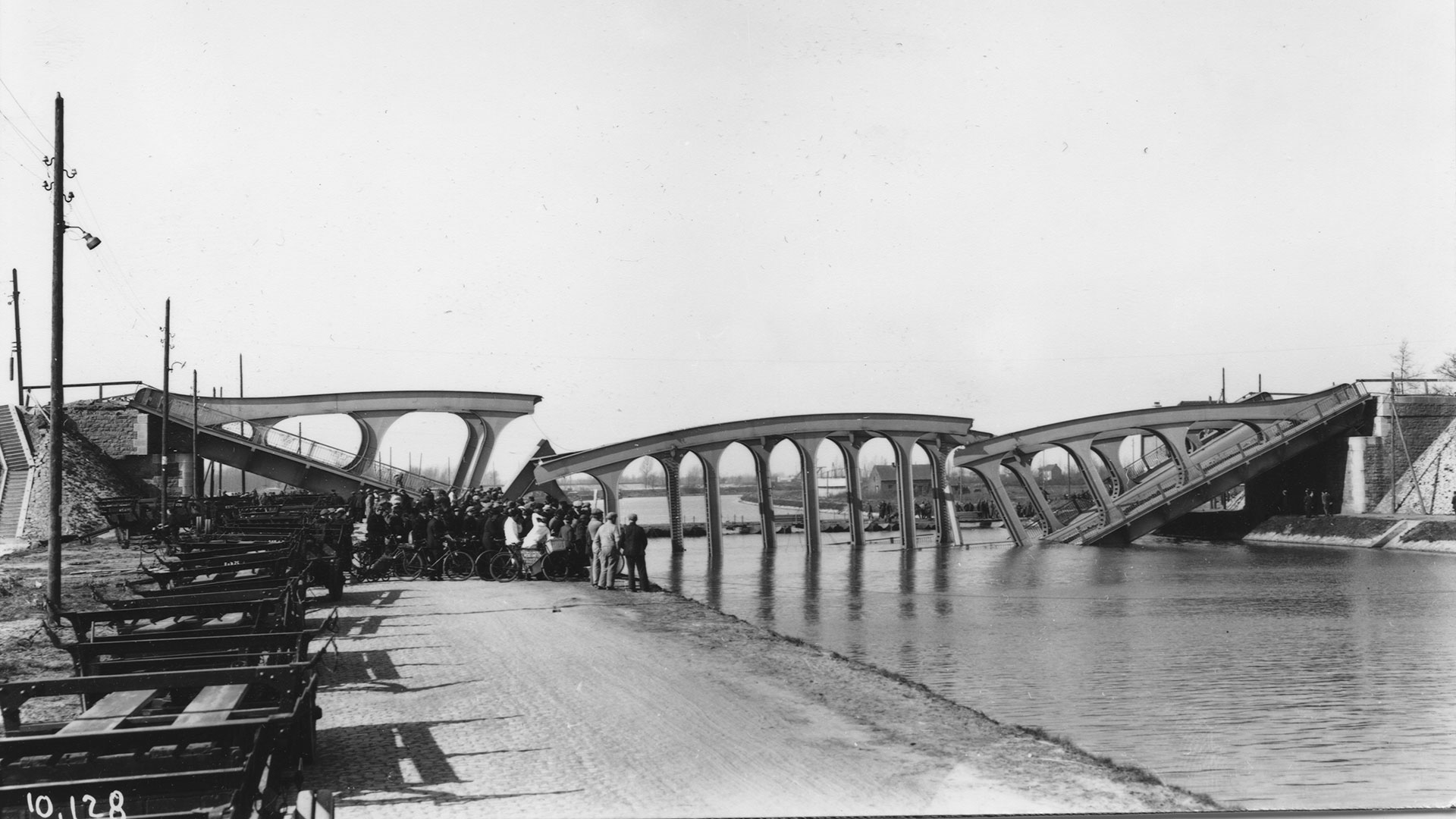

POSTPONED – ‘The Vierendeel bridge story’ by Bernard Espion

LONDON Alan Baxter Gallery 75 Cowcross St, Clerkenwell, LondonDUE TO INDUSTRIAL ACTION THIS EVENT HAS BEEN POSTPONED [...]