‘Float Glass Development and Process History – A Revolution’ by Gerry Miller

22nd March 2022 @ 6:30 pm - 7:30 pm

An in-person meeting presented by Gerry Miller

The development of processes for the manufacture of Flat Glass was slow, progressive in only minor ways for many decades from 1900 to 1960. The methods used had become automated but still had many basic problems, particularly in the visual quality of the glass. They were all labour intensive, inefficient in performance and had problems keeping up with the product demands of the consumer industry. All flat glass manufacturers worldwide were looking for a step change to move forward, but for 30 years little had really changed.

Pilkington was the world leader in the technology of producing Polished Plate Glass, used for the most demanding markets and they had patents to protect their technology. In the 1950’s the main board of Pilkington, a family-owned private company, decided to undertake a revolutionary path in exploring the possibilities of producing high quality glass using a new technology. Their determination and technical expertise took them into an unknown world at great development cost for many years, far longer than ever expected, before they found success with the process known as Float Glass.

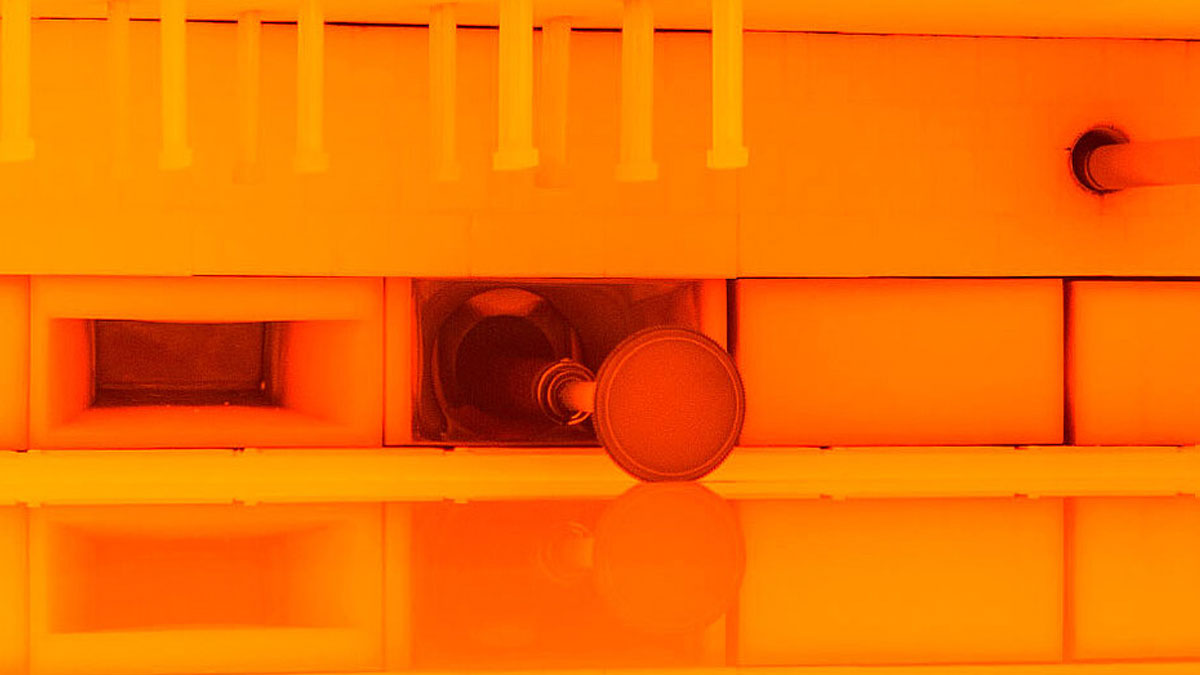

This process was a revolution, floating molten glass on a bath of molten tin to produce a perfectly formed product, free of distortion and capable of meeting the needs of all markets in a single process. This method has since become the only significant manner of producing Flat Glass today and has lasted for more than 60 years using the same basic principles. Technical advancements have been made in later years to cover all universal demands for modern glazing requirements, the application of coatings and colours to enhance both their functionality and appeal.

About the Speaker

Gerry Miller has worked in the glass industry with Pilkington all his life, including for the last 18 years as an independent consultant internationally, mainly on the Float Glass process.