‘The Closed Cycle Gas Turbine’ by Dr Fred Starr

April 18 @ 7:30 pm - 9:00 pm

Joining us IN PERSON – just turn up, there’s no need to register.

Joining us ONLINE – Please click this Zoom Link 10 mins before event to join us (to be added).

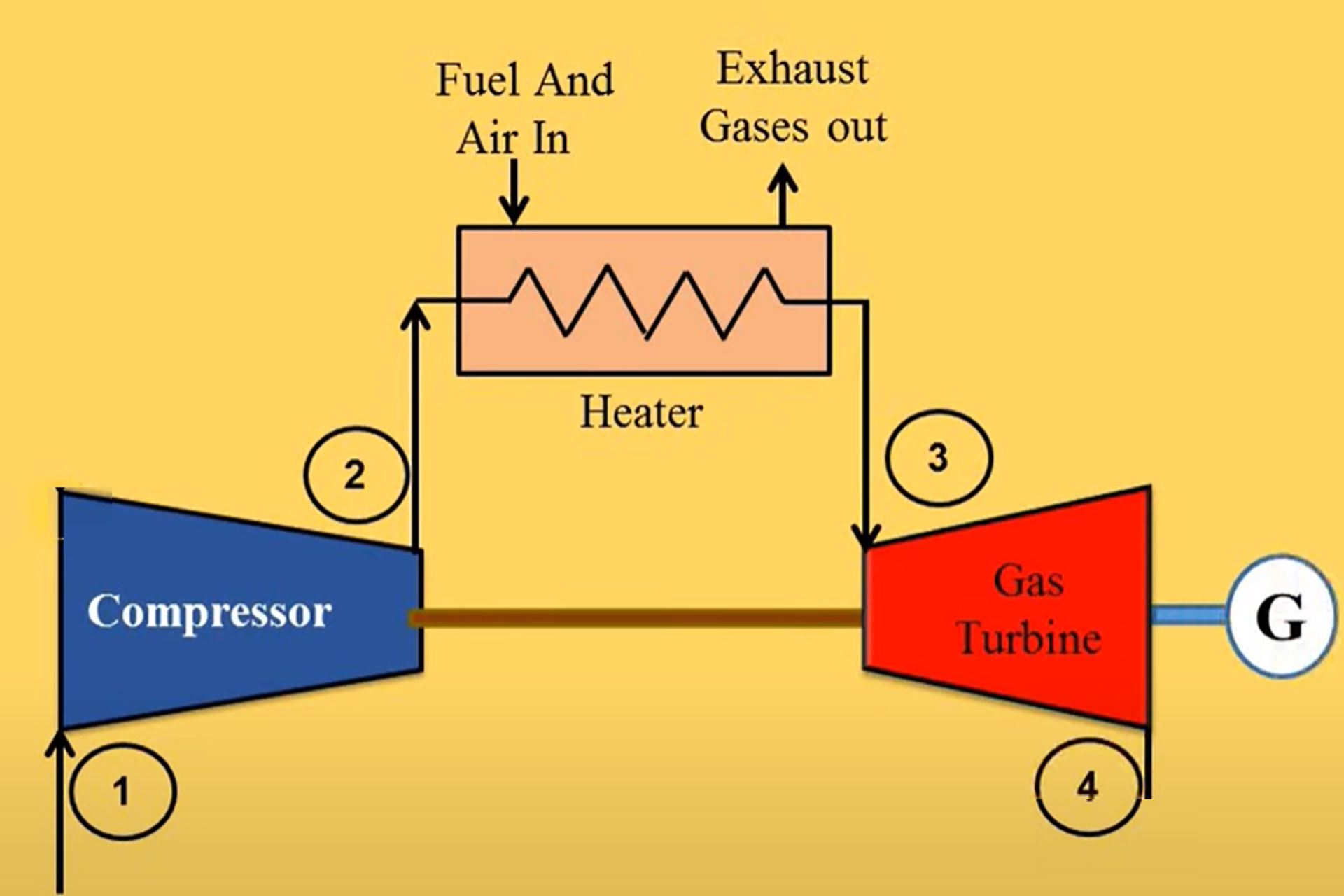

This talk is about the Closed Cycle Gas Turbine but Dr Fred Starr will also discuss the CCGT or Combined Cycle Gas Turbine, which supplies up to 65% of Britain’s electrical power when the wind isn’t blowing or the sun isn’t shining. In actual fact, in the section of British R&D, in which he worked, the Closed Cycle Gas Turbine project was deliberately set up to compete with early forms of the CCGT. The Closed Cycle Gas Turbine uses pressurised air, helium or argon, in a sort of continuous closed loop. It uses a complex and efficient thermodynamic cycle, giving a potential advantage over aero-derived and industrial gas turbines.

The closed cycle was invented in Switzerland in the 1930s, at Escher Whyss AG. But another Swiss company, Brown Boveri AG, had twenty years experience in the development of the gas turbine for industrial use. Its efforts culminated in the world’s first industrial gas turbine at Neuchatel in 1939. There was obviously a flow of information between the two companies, even though they were in competition.

The principal advantage of the Closed Cycle Gas Turbine is that it can use coal or heavy oil, an impossibility with normal gas turbines. In the post war era, a number of units were built in countries that had good coal supplies but were short of oil, and where district heating was common. There was sporadic interest in Britain using peat as a fuel and waste heat from a gas works and some blue skies thinking with the closed cycle in nuclear powered aircraft. The big shortcoming of the closed cycle was that improvements in efficiency demanded a “heater” with tubing that had more high temperature strength and better resistance to corrosion from coal and heavy oil ash. In consequence, interest died, apart from a German led programme using a pebble bed high temperature nuclear reactor.

The British Gas effort, around 1990, was built around the realisation that a new range of “mechanically alloyed” high temperature steels had been developed, and that natural gas, when burnt, does not produce a corrosive ash. Dr Fred Starr “sold” the idea of a high temperature closed cycle to his Assistant Director, GH Gibson and was told to get on and build a “demonstrator”. This was to test out this new high temperature heater, and incorporate all the salient features of a Combined Cycle Gas Turbine. There will be a brief run through of pictures of the installation.

Real advances in the nuclear field will come from concepts like the Molten Salt and Molten Lead Reactors. If these were to come about, the Closed Cycle Gas Turbine fits in very well with these sources of high temperature heat.

About the Speaker

Dr Fred Starr graduated as Metallurgist from Battersea College (now the University of Surrey) in 1966. After a short period, training to be a shift engineer on a steam reforming plant at Hitchin, he joined British Gas, London Research Station, in Fulham where he remained for 30 years. Initially he did failure investigation on steam reforming plants, some of which included visits to the sites at Breakwater, Plymouth, and Seabank, Bristol. In this respect, a big regret was not knowing that the Newcomen Society used to meet at the Science Museum, just up the road from where he worked in Fulham.

Much of Fred’s time at London Research was spent on materials for high temperature gasifiers. When this work terminated, he came up with novel ideas for generating electricity using natural gas. This included the concept of incorporating a Stirling Engine within a gas boiler, and the Closed Cycle Gas Turbine project. His deep interest in aircraft and aircraft engines and background in steam reforming were key to the success of the Closed Cycle Gas Turbine “demonstrator”. Privatisation killed real R&D, and he left British Gas in 1996. Fred’s most important job after leaving British Gas was with the EU’s Joint Research Centre in the Netherlands, where he did the basic design for a HYPOGEN plant making hydrogen from coal. Despite this, he is extremely cynical about the hydrogen economy.

Formally “retiring” in 2007, Fred became an active member of the Newcomen Society. With the help of Bryan Lawton, John Anning and Ed Marshall he got the Society to put on a conference on The Piston Engine Revolution (the development of the IC engine). Later on, he came up with the Swords into Ploughshares conference (how WWI transformed British Engineering).